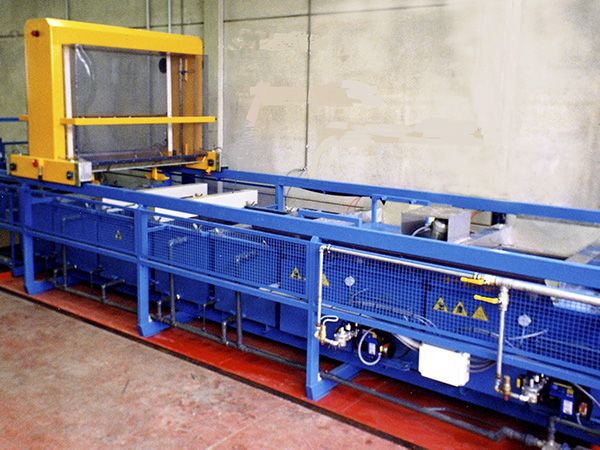

Automatic iron burnishing system made up of 2 burnishing tanks

Automatic iron burnishing system intended for metal colouring, obtained by electrolysis, using special solutions.

Iron burnishing, particularly chemical burnishing, is based on the immersion of the piece in baths at high temperatures and on the subsequent chemical action of the substances dissolved in the solution.

The colouring obtained by burnishing is the result of the formation of particular compounds, mostly oxides and/or sulphides, which are on the surface of the objects.

Details of the iron burnishing system

The proposed iron burnishing systemis made up of 2 burnishing tanks with heating performed by methane gas burners with flame reversal, by means of radiant tube heat exchangers, specifically designed and sized.

The large pieces are generally processed in special baskets, while the small metal parts are treated by barrels made of stainless steel.

Productivity

Dimensions